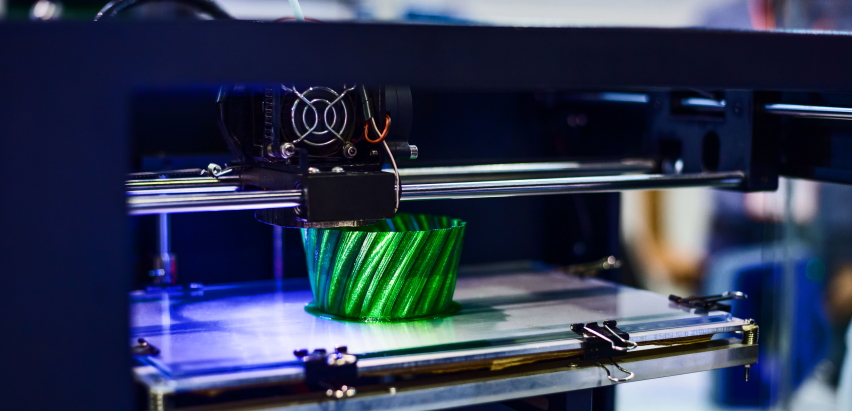

The substances utilized in 3d printers are as varied as the items created as a result of the process. As a result, 3D printing is versatile sufficiently to allow producers to customize a product’s structure, appearance, and toughness. Greatest of all, the characteristics can be attained with significantly fewer steps than are generally necessary for standard production methods. Furthermore, these items can be created using different types of 3d printing materials.

Top Materials Used For Industrial 3d Printing

Components for 3D printing come in a variety of shapes and sizes. Thermoplastics are used in the majority of commercial 3D printed articles. Scientists and developers prefer to make working prototypes out of 3D printing materials with similar or identical material qualities as the finalized product. Plastics, which come in a thread, polymer, grain, and fine powder, are the most extensively used 3D printed substance. The majority of plastic 3D printing ingredients can be utilized in both household and industrial settings. Let’s talk about it in the following 3d printing materials guide.

- Plastic – The Most Common Printing Material

Plastic is by far the most widely used raw material for 3D printing today. One of the most versatile substances for 3D-printed games and domestic fittings is plastic. Office equipment, pots, and action figurines are among the items manufactured using this technology. FDM printers are used to make plastic goods, which liquefy and mold thermoplastic fibers into pattern layer-by-layer. The plastics used in this method are typically manufactured from one of the components like Polyastic acid, Acrylonitrile butadiene styrene, Polyvinyl Alcohol Plastic, or Polycarbonate.

- Metal—A Widely Used Printing Material

The aviation, pharmaceutical, and automobile industries all rely heavily on metals. As a result, 3D printers that use metals as a 3D printing element are just as vital as those that use plastic or other materials. These materials are designed to print complicated geometrical patterns and more refined designs with great detail. However, 3D printing with these materials is complex and requires a high level of expertise. As a result, 3D printers that use these substances are used in corporations and large-scale manufacturing facilities.

- Stainless Steel—The Most Cost-Efficient Material

Stainless steel is one of the most common materials for 3D printers since it is the more cost-effective of all the alloys. The metal’s hardness is well-known over the globe, and it’s ideal for a variety of projects that demand large, robust pieces. During 3D printing using Steel Material, one can create a wide range of shapes, from commercial to aesthetic. The magnetic characteristics of the 3D printing substance are good. If you want to paint it, plating it is a way to provide it a gleaming finish.

A visit to one of our stores is a must if you are a serious tool user. Events and Demonstrations are regularly held at our stores giving you the opportunity to see the latest machinery, tools and accessories in action and even the chance to ‘Try before you buy’. Don’t miss our In-store Events

A visit to one of our stores is a must if you are a serious tool user. Events and Demonstrations are regularly held at our stores giving you the opportunity to see the latest machinery, tools and accessories in action and even the chance to ‘Try before you buy’. Don’t miss our In-store Events